|

Vortex Popcorn™ machine Robopop® is a new type of machines, which pops kernels using revolutionary technology.

|

Robosugar is revolutionary machine for caramel popcorn coating.

|

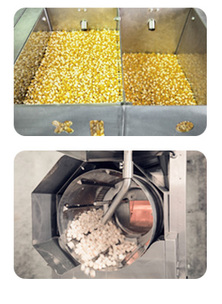

Vortex Popcorn™ machines Robopop® are designed on the basis of a new patented technology, due to which corn is rapidly heated, popped and vortexed away from the hot zone immediately after popping.

Corn evenly distributes over parabolic bottom of the machine internal chamber, constant corn rotation around the chamber axis and simultaneous agitation takes place in the chamber. This process provides fast and uniform corn heating. Owing to the artificially created vortex air stream inside the chamber, popcorn is immediately withdrawn from the hot zone after popping. That profoundly improves popcorn taste and quality. Further, popcorn falls into the sifter, which separates husk and unpopped corn kernels from perfect quality popcorn.

- Vortex Popcorn™ machine Mini Robopop® 25 (VPM-MRS2FUS) (Production capacity – up to 12 kg/h)

- Vortex Popcorn™ machine Robopop® 60 (Production capacity – up to 28 kg/h)

- Vortex Popcorn™ machine Robopop® 75 ! NEW ! (Production capacity – up to 34 kg/h)

- Vortex Popcorn™ machine Grand Robopop® 220 (Production capacity – up to 100 kg/h)

- Industrial Vortex Popcorn™ Production Line ROBOPOP FACTORY (Production capacity – up to 500 kg/h)

Fully automatic machine Mini Robopop® 25 has a production capacity up to 12 kg an hour and makes perfect popcorn for further caramelization and coating. Possibility to control turbine’s speed allows configuring the popper even for low-quality corn kernels. The machine is easy to maintain, by removing the side door you will have a full access to the chamber.

Mini Robopop® 25 is delivered already assembled and after unpacking is ready to be turned on.

Popcorn is not fried in oil; as a result there are no trans fats and carcinogens

Automatic batch-by-batch operation

Will pop small batches every 2 minutes with automatic reset

Suitable for both Butterfly and Mushroom corn

Fully automatic

Direct drive turbine – no belt drive and bearing assembly

-

Throughput – up to 12 kg/h (25 Lbs/h)

-

Power requirements – single phase 230/208 Vac 50/60 Hz, 6 kW

-

Dimensions – 1070x580x1600 mm

-

Weight – 150 kg

Robopop® 60 production capacity is up to 28 kg per hour. The machine is equipped with an intellectual control system that makes the whole process fully automatic with minimum operator’s involvement. Robopop® 60 is equipped with a multi-drop oiler and a salt seasoner and can pop both ready-to-eat salty snack and mushroom corn for further caramel coating. It has two separate 15kg corn hoppers for butterfly and mushroom corn and operator can easily switch between corn types. Robopop® 60 can be operated intuitively by the touch screen so the popper will be ideal solution for cinemas.

Robopop® 60 has a warming compartment for two big oil cans; oil nozzle warms up during popping excluding the possibility of oil freezing.

Popper is delivered assembled, after unpacking it is ready for operation.

This model is equipped with two carts for popcorn.

Automatic continuous operation

No oil is used for popping; no carcinogens, no trans-fats, and production cost is lower

Built-in automatic salt/oil application system for making classic Butterfly popcorn with oil and salt

Suitable for both Butterfly and Mushroom corn

Equipped with double feeder for quickly switching between corn varieties

Fully automatic and adjustable flavoring and salt seasoning

Equipped with bag overfill and low corn level alarm sensors

Has a warming compartment for two standard 22 kg oil buckets; oil nozzle warms up at popping excluding oil solidification

Power requirements – 3P 400/208 Vac 50/60 Hz, 11.3 kW

Dimensions (LхWхH) - 1430х600х1700 mm

Weight - 250 kg

Fully automatic machine Robopop® 75 with throughput rate up to 34 kg/h (75 Lbs/h). Built on patented Vortex Popcorn™ technology. Easy to operate, maintain, and clean. Delivered fully assembled and ready to operate once plugged in.

Vortex Popcorn™! No oil is used for popping; no carcinogens, no trans-fats, and production cost is lower

Vortex Popcorn™! Popped corn is immediately removed from the hot area, thus its nutritional value is kept as much as possible

Automatic batch-by-batch operation

Suitable for both Butterfly and Mushroom corn

-

Throughput rate – up to 35 kg/h (75 Lbs/h)

-

Power requirements – 3P 400/208 Vac 50/60 Hz, 11.3 kW

-

Dimensions – 1370x600x1690 mm

-

Weight – 200 kg

Fully automatic machine Grand Robopop® 220 is ideal for industrial popcorn production. Production capacity of the machine is up to 100 kg per hour. There is a possibility to control turbine’s speed to configure the popper even for low-quality corn kernels. The machine is easy to maintain, by removing the side door you will have a full access to the chamber.

Automatic batch-by-batch operation

Suitable for both Butterfly and Mushroom corn

High output

Healthy product: corn kernels are popped in the vortex of hot air

Delicious product: crunchy and tender, no difference from movie-style popcorn

Fully automatic, minimal operator involvement

Direct drive turbine – no belt drive and bearing assembly

-

Production capacity – up to 100 kg/h (220 lbs/h)

-

Hopper capacity – 25 kg

-

Rated voltage – 3P 400 Vac 50/60 Hz 24 kW (3P 208 Vac option is available upon request!)

-

Dimensions – 1690x1220x1930 mm

-

Weight – 300 kg

Robopop Factory is our fully automated industrial line for savory and caramel coated popcorn production. Using revolutionary Vortex Popcorn™ hot-air popping technology the line produces ready-to-eat Butter Flavored Popcorn (Curry, Paprika or Tomato, even Masala or a variety of other spicy flavors!), as well as delicious Caramel or Cheese… With RoboLabs, the caramel is not cooked in advance or heated for excessive periods of time. Instead, it is only prepared immediately before coating. This allows you to use natural flavors and fragile natural colors that do not withstand the competitor’s processes!

- Production capacity – standard production capacity up to 200 kg/h (440 lbs/h), can be extended up to 500 kg/h (over 1100 lbs/h)

- Nominal power 135 kW (3 phase 400 Vac 50\60Hz)

- One person operated

- Fully automated

- High output: from 100 kg/h up to 500 kg/h

- Scalable configuration

- Suitable for savory and caramel popcorn production